A sustainable method for extracting rare earth elements from electronic waste

A US research team has designed an ‘environmentally friendly and economically viable’ method for recovering rare earth elements from electronic waste. It is cheaper than traditional methods, uses less water, acid and energy, and emits fewer greenhouse gases, according to the authors in PNAS. Rare earth elements (REE) are a group of chemical elements needed to manufacture batteries, magnets and electronic components. Both the European Union and Spain are committed to these critical materials in order to reduce their dependence on foreign sources.

250929 tierras raras EN

Martín Muñoz Morales

Professor and researcher in the field of Chemical Engineering at the School of Agricultural Engineering, Forestry and Biotechnology at the University of Castilla-La Mancha

This study is particularly relevant as it aligns with the strategies of Spain and the European Union aimed at developing alternative routes to traditional mining for obtaining rare earth elements (currently dominated by the Chinese market) and reducing their associated environmental impacts.

Two aspects stand out among the main innovations compared to previous work:

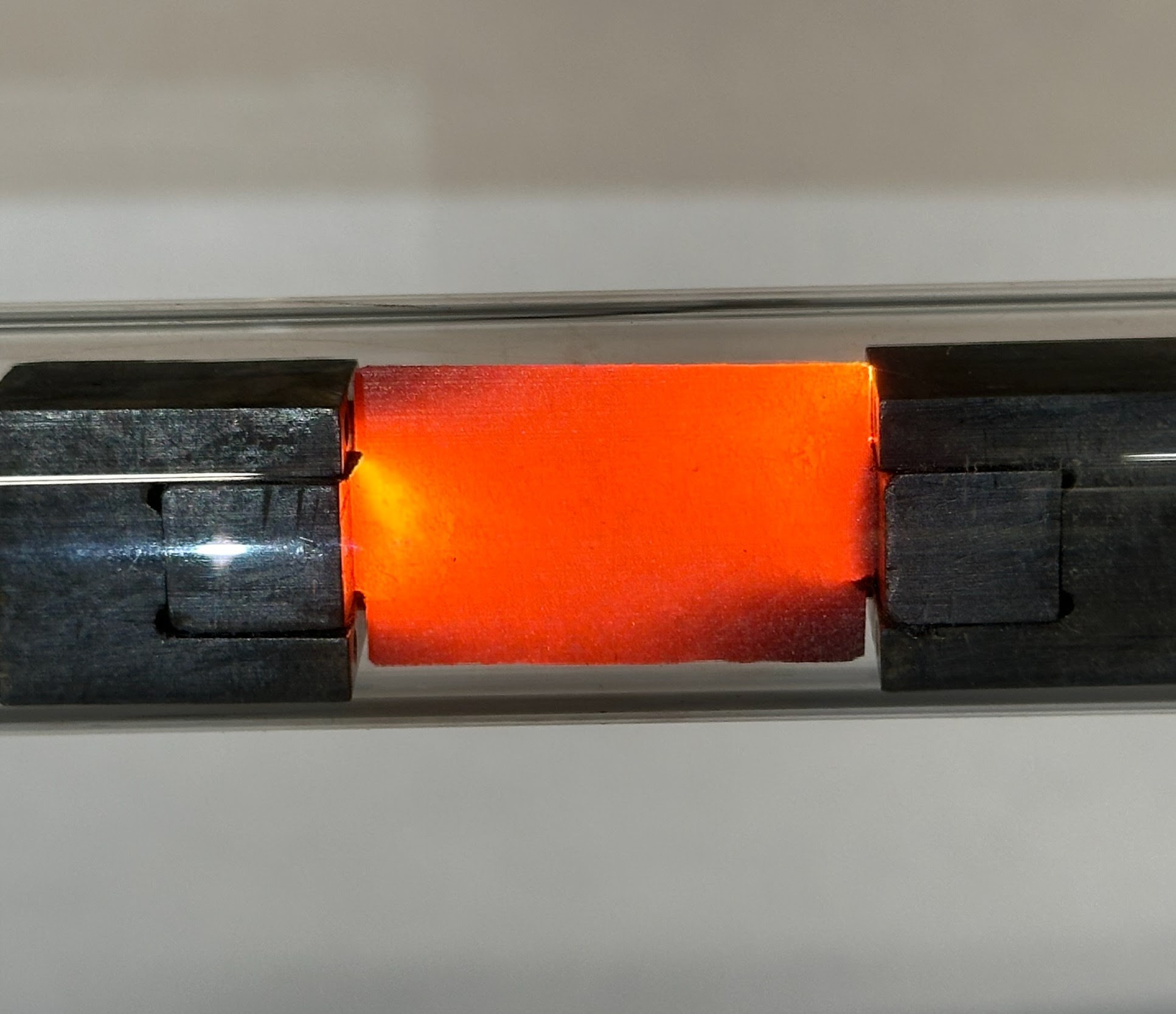

- Elimination of the use of large volumes of contaminated and acidic water in the extraction of these metals. This is possible thanks to the application of instantaneous Joule heating combined with chlorination (FJH-Cl2), which allows the process to be carried out completely without water or acids. This aspect is particularly significant, as it is often used by neighbourhood platforms to oppose the exploration of land that may contain minerals with these elements.

- Good capacity to selectively recover samarium (Sm) and neodymium (Nd) at high purities (99% and 96%, respectively) without using toxic solvents. These are two obstacles which, if effectively overcome, would make the recovery of REEs from waste competitive with mining extraction processes. Without them, as has been confirmed so far, these recovery processes would not be competitive.

This context promotes environmental sustainability, in addition to reducing greenhouse gas emissions, by promoting alternatives that avoid the generation of liquid effluents characteristic of hydro and pyrometallurgical technologies. Similarly, it improves economic competitiveness by enabling the direct commercialisation of the recovered elements and reducing the energy consumption of this stage.

Conflict of interest: "I am currently involved as a researcher in the GEOCENTRIC project (Integration of the circular economy in the decontamination and recycling of waste with high metal content), jointly funded by regional funds from the European Union and the Regional Government of Castile-La Mancha through the CLM Research and Innovation Agency (INNOCAM)".

Shichen Xu et al.

- Research article

- Peer reviewed