Two low-pollution alternatives proposed to extract lithium from diluted brines like seawater

Lithium, a material widely used for battery production, is typically extracted from rocks and concentrated brines, but these reserves are expected to run out by 2080. The alternative is to evaporate more diluted brines (such as seawater), but the traditional process is inefficient, polluting, and consumes large amounts of water. Two new studies published in Science propose two more viable and environmentally friendly alternative methods: the first uses a membrane that filters lithium through a transpiration system similar to that of plants, requiring only solar energy. The second combines electrodes to mimic a battery and move lithium from the brine (cathode) to fresh water (anode).

Alicia Valero Delgado - extracción litio EN

Alicia Valero Delgado

Professor of Machines and Heat Engines at the University of Zaragoza, and Head of the Industrial Ecology group at the Energaia Institute

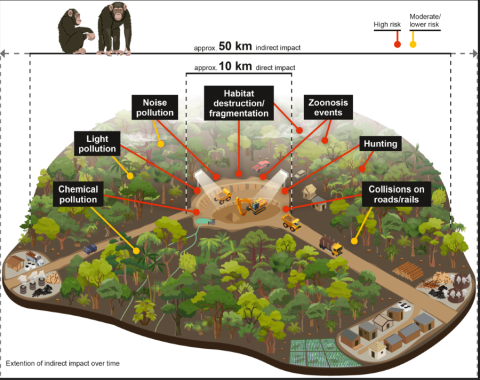

I see this as good news. Currently, increasing amounts of lithium are being extracted either from rocks (mainly spodumene from Australia) or from brines in the lithium triangle (Argentina, Chile, and Bolivia). In the Atacama Desert in Chile or in Uyuni in Bolivia, lithium extraction results in the destruction of unique habitats in the world, with incalculable ecological value. The reserves in the brines are large, but the damage is irreversible. Therefore, extracting lithium from brines — waters with a high salt concentration, like those of the Dead Sea, as proposed in an article, or even from desalination brines — is an interesting alternative. Until now, this hasn’t been done due to the high cost, especially the energy cost.

If, as the articles suggest, the energy cost can be substantially reduced, the potential to expand reserves at a low cost is very promising, given the enormous lithium demand that is expected, especially for electrifying transportation. This would also allow for a reduction in supply risks, as it could be extracted from many more places. I also think it is interesting how they have approached the problem through biomimicry: learning from nature to replicate it in industrial processes. After all, nature has optimized its processes over billions of years. We have a lot to learn from it!

Martina Gamba - extracción litio EN

Martina Gamba

Researcher at CONICET, in the Center for Mineral Resources and Ceramic Technology at the National University of La Plata (Argentina)

The study offers a technological proposal to extract lithium using an electrochemical method that operates similarly to a battery. The novelty of the cell used is that it avoids the use of membranes (and the disadvantages associated with them) and consists of a simple, easily scalable design. The work is important because it reports the extraction of lithium from diluted solutions and takes advantage of the osmotic potential between the brine and the extraction water to reduce energy consumption.

The device was tested using both synthetic and natural brines (from the Dead Sea) at laboratory and pilot plant scales, achieving lithium recovery rates of over 90% at the laboratory scale and 80% at the pilot scale, while also saving 21% of energy costs. The lithium selectivity values were higher than those of other electrochemical methods that use membranes, and the calculated extraction cost was competitive with that of lithium extraction from conventional resources.

However, when evaluating direct lithium extraction technologies, it is crucial to consider other parameters beyond just economic cost, energy consumption, or lithium recovery performance. For example, there is no explicit calculation of the amount of fresh water the process requires. In fact, the authors mention that due to time limitations, they did not reach the necessary lithium concentrations to later precipitate it as Li2CO3 by adding Na2CO3 (the final product for commercialization) and therefore used a solar evaporation stage. Direct lithium extraction technologies should avoid water evaporation entirely, whether in the pre-concentration stages or in obtaining the final product. Additionally, it is crucial to develop technologies that move towards the simultaneous recovery of as many by-products as possible from a single deposit. These perspectives are fundamental for drastically reducing the consequences that lithium-related mining activities generate in the territories.

Zhen Li et al.

- Research article

- Peer reviewed

- Modelling

Yan Song et al.

- Research article

- Peer reviewed

- Modelling